Fei Hong’s Soft Power: Product Design Capability

Introduction

Product design capability is not only a crucial step in the product development process but also a key factor for the success of a business. It influences product quality, cost, innovation, customer satisfaction, and shapes the market image and competitive advantage of the company. In this fiercely competitive era, our company takes pride in showcasing outstanding product design capabilities.

Key Aspects of Design Capability

Even with systematic and standardized design processes, there are many challenges and difficulties in the design process. The following three capabilities are crucial in helping us overcome obstacles and demonstrating design competency:

Attention to Detail: Attention to detail is a critical ability to ensure design quality and accuracy. Designers need to carefully observe details, ensuring the precision of every design element to optimize the product’s appearance and functionality. Prioritizing attention to detail avoids the need for costly error corrections or changes in production techniques during the manufacturing process and provides users with a better experience.

Patience: Even with standardized professional design processes, it may still take a significant amount of time. When designers face challenges and setbacks, patience is essential. Patience enables designers to persist in their dedication to product projects, problem-solving, and continuous improvement.

Communication:Communication is a vital skill during the design process because designers need to interact effectively with supervisors and various departments in the factory. Being able to clearly express ideas, requirements, and design decisions, and listening to feedback and suggestions from others, empathizing with their perspectives, enhances collaboration efficiency.

Product Development Process

Discussion and communication are needed continuously in every design process to transform product design into actual market products.

- Product Positioning/Conceptualization:

Conduct market research, gather relevant data, understand industry trends, and attempt to grasp the needs of the target customers. The goal is to determine a unique product positioning aligned with the product’s core value proposition. - Hand Sketches:

The first step in visualizing the core concept of the product. Hand sketches may not be comprehensive, but they help visualize concepts, facilitating discussions and improvements. - Preliminary Model Testing and Evaluation:

We may use various methods to create preliminary models, including paper models, 3D printing, or other technologies. Preliminary model creation primarily serves to confirm the appearance. The goal is to identify and address potential design issues early to save time and costs in later development. - Dimension Definition:

Determining the product’s size and proportions. This may involve designing technical specifications while considering production techniques, efficiency, and cost to ensure the product can be manufactured practically. - Styling Development:

At this stage, we continue to refine the product’s appearance and structure. This may include improving details, adjusting curves, and more. - 3D Modeling:

3D modeling is the process of digitizing the concept. We use professional 3D modeling software to create more precise digital representations. 3D modeling helps us further test the design, conduct renderings, and perform virtual tests, such as animations. - Color Setting and Surface Finishing (with Prototype Patterns):

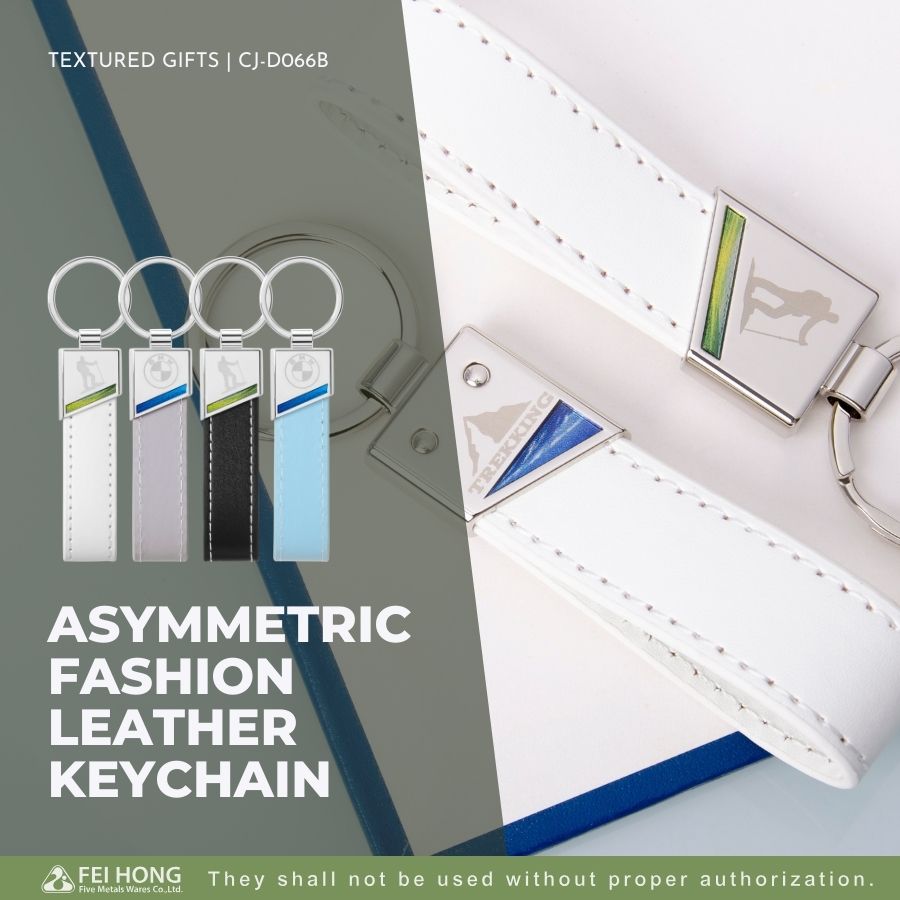

We consider methods for coloring and surface finishing the product. Creating prototype patterns for showcasing on the product, which serves as a reference for production and helps customers visualize their branding logos on the product. - Prototype Production:

Producing prototypes is a crucial step to ensure that the final product adheres to design specifications. Through prototype production, we can physically see the initial form of the product. - Prototype Inspection and Testing:

Inspecting and testing prototypes are key steps to ensure product quality. We conduct inspections, including design appearance, dimensions, and functional testing, to ensure the product matches the original design. - Product Launch:

Once the product has successfully passed testing and verification, we launch it into the market. This includes determining the product’s pricing strategy, marketing activities, packaging design, and distribution channels to ensure the product successfully enters the market, attracts target customers, and achieves business goals.

Conclusion

Built on a foundation of excellent product design capabilities, we specialize in crafting high-quality zinc alloy metal corporate gifts and custom gifts in various materials. Proficient in die-casting, metal plating, and various coloring methods, we maintain an excellent level of product appearance and quality. Through advanced 3D modeling and printing technologies, we can turn concepts into reality and offer customized solutions to meet your unique needs.

If you have initial ideas for branded gifts or products but struggle to visualize them, and you’re looking for top-notch product design solutions, we invite you to collaborate with us. Our design team will provide customized solutions to bring your ideas to life with meticulous attention to detail, making your product stand out in the market.